Plywood is made when thin sheets of wet wood are stuck together into a single sheet with an adhesive.

Heat and pressure are applied to the plywood, forcing it to quickly dry and bond to the adhesive and other sheets of wood until one solid sheet is made from many thin ones.

Getting plywood wet again can damage the bonds between the thin sheets and adhesive.

Can Plywood Get Wet?

Yes, some plywood can get wet, but not for very long if you can help it!

Plywood is water-resistant at best.

Small isolated incidents of water exposure are fine and will not completely ruin your plywood like it would a suede jacket, but extended exposure without the right waterproofing treatment can cause long-term harm.

There is no completely waterproof plywood on its own, but it may be made waterproof by way of special sealants and oils.

Some plywoods are naturally more resistant to moisture than others, and different grades of plywood have different levels of resistance.

Most plywoods can tolerate a little bit of water contact for a short period of time, especially if you are proactive and remove the moisture source to let the wood dry out.

Even still, it is generally best to prevent moisture from getting to the wood at all.

There are different grades of plywood with different advantages and disadvantages, as listed below:

Pressure-Treated plywood

Plywood treated with chemicals that increase resistance to mold and mildew.

This kind of plywood can withstand a lot of humidity, and is the second most tolerant type of plywood to wetness due to the chemical used in the pressure-treating process, but should never be left submerged in water.

CDX Plywood

the most common and most affordable option, sturdy but with a rough and undesirable look to its surface.

This kind of plywood is the worst to expose to long term water or humidity, as it is not high grade wood and is very vulnerable to warping.

ACX Plywood

The more expensive option, used when the plywood’s exterior will be visible because of its better appearance.

This kind of plywood is much more resistant to warping than CDX because of the higher grade of wood used. It can tolerate a fair amount of moisture.

Marine Plywood

This one is the highest quality, heaviest, and most expensive because of its appearance and strength.

This type of plywood is the most water-resistant, which is why it is commonly used to make boats.

Overlaid Plywood

Not unlike ACX or CDX but is more attractive with a better finish. Due to this finish, it has much more durability against the elements than ACX or CDX.

Oriented Strand Board (OSB)

This is technically not plywood,rather a specially formulated plywood substitute that works best when only partially exposed to the elements, if at all.

Often used in construction, since the process of building a house leaves a fair amount of plywood temporarily exposed to the elements. OSB handles this limited exposure well.

T1-11 Plywood

Usually used for siding due to its lighter construction, as it won’t collapse on its own weight. It is a cheaper option, but it is also very vulnerable to the elements unless it is regularly resealed and well maintained.

This plywood is more often used in places like Arizona or Nevada where there is little to no rain or humidity.

Apart from expense and appearances, each kind of exterior plywood has different weights and thicknesses to consider.

These differences help inform us of their most useful applications, but more on that in another article.

What Happens When Plywood Gets Wet?

Getting your plywood wet for too long or with too much water can lead to real problems.

Untreated and unsealed plywood that gets wet during construction can undo hours of work and even make existing structures unsafe if left unchecked for too long.

Rain on the subfloor during construction can cause the most issues, especially if it is not allowed to completely dry before construction continues. Plywood roof sheathing can also get wet and cause roof issues, leaks, and in drastic cases, collapse.

Plywood is made when wet, swollen sheets of wood and glue are pressed together by pressure and heat to dry and bond them to make one uniform board.

Prolonged exposure to moisture lets the wood soak up the water and swell up again, which limits the glue between the layers’ ability to hold them together.

This leads to issues like warping, separation, splitting, and even rot:

1. Warping

When the moisture causes the plywood to expand and then contract when it dries, it can bend out of shape. This process is called warping.

The board may become slightly curved or go as far as to buckle entirely, like a useless modern art installation.

When severe warping has occurred, the only thing to do is get a new board.

If the warping is very minor, you may stack the warped plywood bow-side up sandwiched between two other sheets of plywood.

Make sure not moisture can get to the plywood during this process. Add weights to the top of the uppermost board, and let pressure do its work, then check for completion every couple of days.

2. Separation

Moisture causes the individual thin layers of the plywood to swell and push each other apart, while also weakening the glue’s adherence between the thin sheets.

Sometimes the water eats away at the glue itself, dissolving it and further weakening the structural integrity of the plywood board.

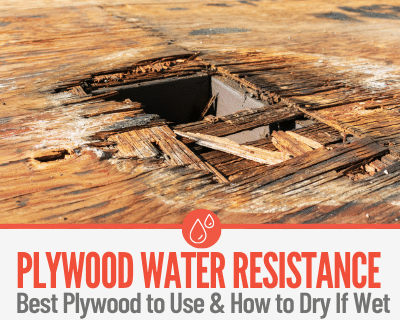

The thin sheets of wood can come apart, weakening the board and rendering the plywood useless. Separated plywood cannot be repaired and must be replaced.

3. Splitting

If things are already going wrong, you may get splitting. This can (and often does) happen c0ncurrently with warping and separation.

Splitting is when the board visibly “cracks,” or splits, from the pressures of swelling and or the stress of shrinking back down during drying.

There is no saving this plywood. Splitting plywood cannot be repaired and must be replaced.

4. Rot

This is often the worst case scenario for water-damaged plywood. The moisture in the plywood may not completely dry out, which allows fungus, bacteria, mold, or mildew to attack the wood.

This can make the plywood smell awful, which nobody wants in their home.

It also drastically weakens the integrity of the plywood, which can quickly become dangerous if it is structurally supportive plywood. Wet rot is the easiest to notice because of the staining and smell.

Dry rot is the silent killer of plywood.

By the time you notice the dry rot caused by fungal organisms in the wood – it is too late and the wood is already structurally compromised.

There is no saving this plywood. Rotting plywood cannot be repaired and must be replaced.

Water Damaged Structural Plywood?

Call 844-488-0570 for a Risk Free estimate from a Licensed Water Damage Restoration Specialist in your area.

We Can Help Dry out your Plywood Subfloors & Structural Plywood , as well as Repair any Water Damage Caused.

How to Dry Wet Plywood

1. Remove the Water & Deal with the Source causing the plywood to be wet

If it is a leak, plug it. If it is sitting in a puddle, remove it from there or drain the area as best as you can. You get the idea.

Get a bunch of clean, dry rags and wipe the plywood down as best as you can to try and absorb all the surface moisture.

Carefully dry the edges as well if you can, as they are the most vulnerable part of the plywood sheet.

2.Use Fans For Good AirFlow

Use fans or ventilation to get airflow through the area the plywood is drying to expedite the drying process.

If possible, remove the plywood from where it is installed to get the edges exposed to the drying process.

The edges are the most moisture-vulnerable.

If stacking plywood, put cinder blocks or something similar between the layers to space them out and help them dry faster.

3.Turn up the Heat or Lay in Sun If possible

Turn up the heat. Lay them out in the sun if possible.

Set up dehumidifiers or space heaters to dry them out faster.

Note: always monitor any area with a space heater to avoid potential fire and injury.

What is the Ideal Plywood Humidity?

Ideally, there will be no humidity around the plywood, as that can cause the wood to absorb the moisture and swell or warp.

However, most plywood can tolerate holding a moisture content between 5% and 15% by weight. Any more and it may be a cause for worry.

How to Waterproof & Seal Plywood Against Water

Waterproofing plywood against water and moisture is crucial for its longevity and your wallet.

Doing this staves off moisture, warping, separation, splitting, and rot, which saves you money in the long term on repair costs.

Waterproof paints, epoxies, polyurethane, and drying oils are all good options.

To apply most of these and waterproof your plywood, you either brush them or spray them on the plywood, smooth it out once it’s dry, put on a second coat, and then repeat every 2 years.

Waterproof Paints

These are applied by brush painting or spraying them right onto the plywood to make it waterproof.

Let dry fully between coats and do at least two.

The advantage with paints is that you have more options with color and texture, but waterproof paints do not last as long as epoxies do when protecting your plywood.

They may, however, be used in conjunction with epoxies.

Epoxies

These last the longest and dry the fastest, but require gloves and good ventilation to apply.

First step is always to wipe down the wood with a clean dry cloth to remove any dust or detritus. Used as a varnish, you want to put no more than two layers, letting them dry fully between coats, on your plywood to prevent a murky appearance.

Lightly sand between coats to give them grip for the next coat.

Used as a sealant that will be painted over, you want to do 4 layers, letting them dry fully between coats, then lightly sand it down to give the paint something to grip.

This will ensure the best chance of having a truly waterproof plywood.

Polyurethane

You will need a paintbrush along with good ventilation to apply.

First step is always to wipe down the wood with a clean dry cloth to remove any dust or detritus.

Paint the polyurethane on in the direction of the wood’s grain, especially on flat surfaces.

Let each coat dry for at least 24 hours. Lightly sand any drops or blemishes away, then sand the whole board between coats to give it grip for the next coat.

Apply at least three coats.

Oils

You will need a drop cloth and gloves to apply. Gratuitously apply the oil to the wood with a brush or roller, letting it soak in for 10 to 15 minutes.

Wipe away excess oil with a clean cloth to prevent a sticky feeling on the wood.

Allow 12 to 24 hours between coats, and apply at least three for maximum protection.

Best Types of Waterproof Plywood to Use & Best Usage Cases

The best plywood for wet conditions is marine plywood, as it is the most durable, thickest, and strongest.

Unless you live in a houseboat, however, it is unlikely you will use much marine plywood in your home, and your wallet will thank you.

Marine plywood’s heaviness and thickness also makes it dangerous to use as siding, as it may buckle under its own weight.

The list below features the plywood grades with the best strength to cost ratios in the order of most moisture-resistant options, excluding marine plywood.

The best types to use in the construction of any buildings anticipating wet conditions, assuming they are properly sealed first, are:

Overlaid Plywood

The finish on this plywood and the quality of the wood used makes this the best sealed plywood for exteriors that will experience occasional rain or snowmelt.

ACX

This more expensive option is just below overlaid plywood in terms of water resistance when properly sealed.

The wood quality is higher, leading to a better appearance and better longevity and warp resistance when exposed to the elements than most other plywood grades.

Pressure Treated Plywood

This plywood does best in conditions of high humidity without much direct water exposure, if any.

Direct water exposure over time may strip the wood of its antifungal and antimicrobial chemicals over time, ultimately leading to issues like rot or dry rot.

One Strand Board (OSB)

OSB has a slightly higher natural tolerance to moisture than cheaper plywoods, which is why it is used often in the construction of floors and interiors of buildings and homes.

One or two rains won’t ruin it if it dries in an adequate amount of time, but it is used for interiors only for a reason.

CDX

Acheaper option, CDX is best used for interiors or for projects that will not be exposed to much moisture if any.

The wood’s quality is lower, making it more likely to warp and split than higher quality woods that don’t have any knots in them.

T1-11

The cheapest and lightest option, T1-11 is perfect for interiors or as siding for buildings that experience little to no rain.

Deserts, tundra, anywhere precipitation and humidity is nearly unheard of.

It can be sealed to boost its integrity against moisture, but it has to be maintained often which can become costly and tiresome in the long run.

Will Plywood Last Outside?

Plywood can last outside for decades if it is properly waterproofed and maintained.

The dangers to look out for are water sources repetitively dripping onto the plywood, or pooling at its base.

Even one small corner of plywood touching water will ruin the entire sheet over time.

How Fast Does Plywood Rot?

When not properly maintained, plywood can rot within a year, sometimes within just a few months.

Rotting wood always smells bad, but rotting plywood both smells bad AND is severely weakened by the process, which you don’t want in any structures.

In terms of dry rot, fungal spores can germinate inside plywood just seven days after it has been exposed to water and left wet.

Even if it dries after the fact, the spores will survive and slowly eat away at the structural integrity of the plywood.

Once you notice dry rot, it is already too late. The best thing to do is prevent it from happening in the first place.

When to call a Professional

If you believe the plywood in your home has already suffered significant water damage, especially subfloor plywood, do not wait for it to rot and collapse due to the weakening of the wood.

You and your family’s safety is too important to risk.

Call a professional if any of the following are true:

- You are not comfortable safely replacing and/or sealing plywood.

- You have significant water damage to any plywood that is part of the structure of your home or building.

- You notice extensive dry or wet rot in your structural plywood, which may indicate prior or current water damage, respectively.

- You are suspicious of an interior leak inside the walls that has gone undetected for some time and is causing your plywood to swell.

We have Water Damage Restoration Technicians that can help Dry out your Structural Plywood & Repair any Water Damage Caused.

For Disasters of all Sizes,available in 95% of the USA